Challenges with prevalent Stamping & Pressing Monitoring

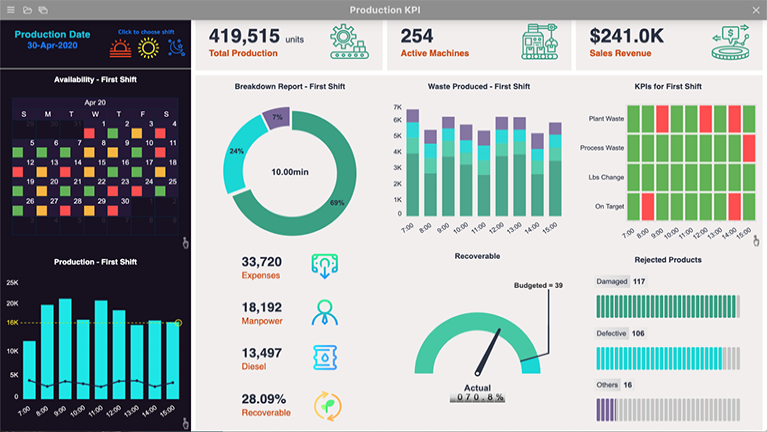

Poor visibility of manufacturing process

Reduced productivity & High downtime

Unoptimized production speed

High repair costs